Plate bending machines Savannah: Mg Precision since 1959

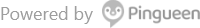

Two rolls F-Line Technology

F Line bending machine is the best solution to bend very little diametres and to obtain the higher industrial productivity.

Upper steel roll and lower motorized roll in special material: The bending with this special roll in urethane allows a faster bending.

With F Line Bending machine the best bending in just one round.

MG designs and builds directly a wide range of automatic machines, that make all the bending process in just one round.

In 2010, Mg Srl became leader in the world scene thanks to creation of the bigger plate bending machine in the world: the “MG32520Z”, is 7,70 mt high, 7,10 mt wide, 13,70 mt long and with a weight of 350 tons, that allows this machine to bend 3 meters wide and 25 cm thick metal sheets.

Three rolls G-Line technology

In the 3 rolls G-Line Plate bending machine the bending rolls move with a planetary movement, reducing frictions and chafings and improving the machine’s bending ability.

HIGH PRODUCTIVITY - BETTER PRECISION IN CONES BENDING – EASY TO USE

3 ROLLS PH LINE WITH VARIABLE GEOMETRY

The new evolution in bending. Variable geometry to make the biggest diametres in the best way. Built with the best materials in the world to give you precision, lenght and flexibility.

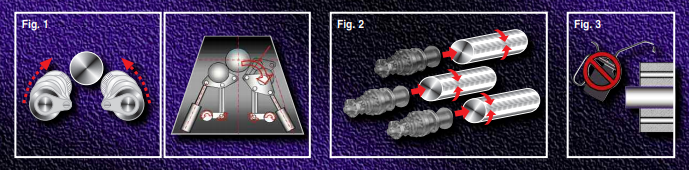

“Four rolls” – M Line technology

The new “Four Rolls” Plate bending machines with more bending power thanks to more powerfull cylinders and engines.

The best flexibility and better performances in the angular works. Equipped with new tested parts.

In addition MG has inaugurated a new standardisation process to improve flexibility in managing components, to reduce time and cost of spare parts and customer service.

“Four rolls” K-Line technology

The K-Line is the new born in MG, with a new way of metal sheet bending.

A four rolls machine mixing hydraulic bending characteristics with a flexibility never seen before.

- Linear Guides

- Direct Transmission

- Permanent Lube

- Angular Rolls

- Movement control and rolls parallelism

- Angular bending system

HIGH PRODUCTIVITY – BETTER PRECISION IN CONES BENDING – EASY TO USE

Thanks to exclusive technology we can ensure you precision and performances able to obtain rings 1.1 times the diameter of the upper roll (for other constructor is 1.3) and standard ability equal to 3 times the diameter of the upper roll (for other constructors is 5 times)